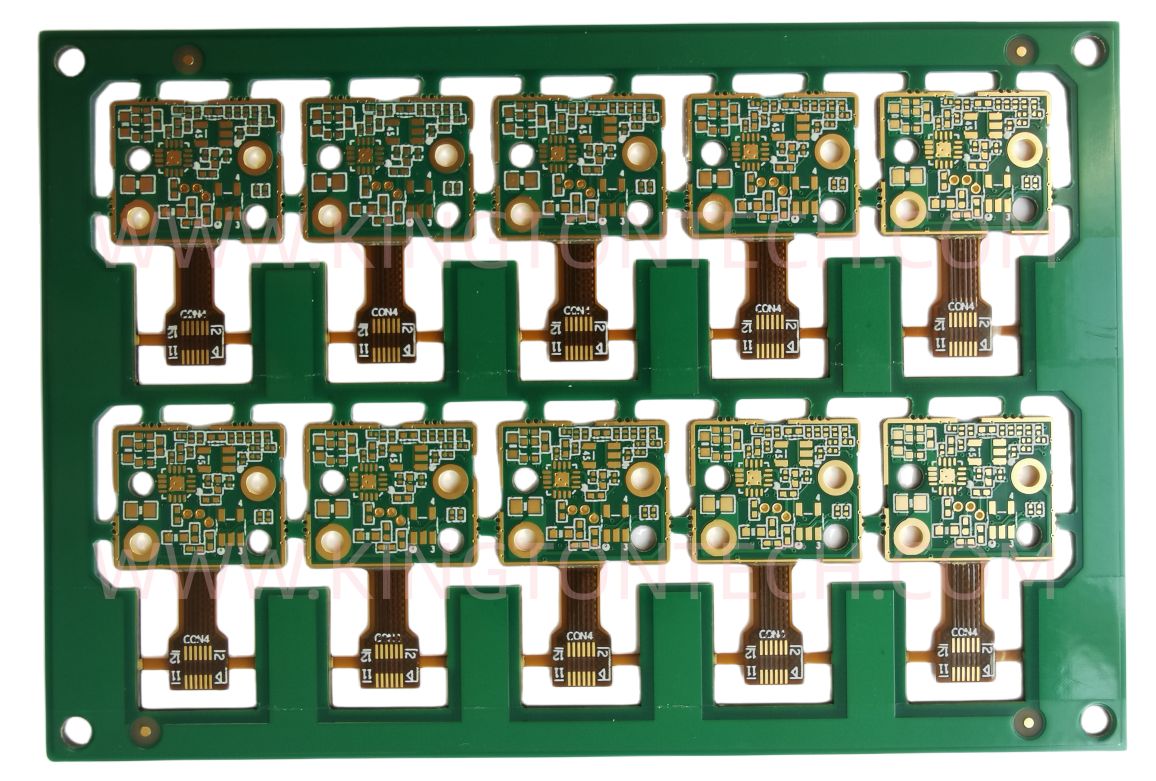

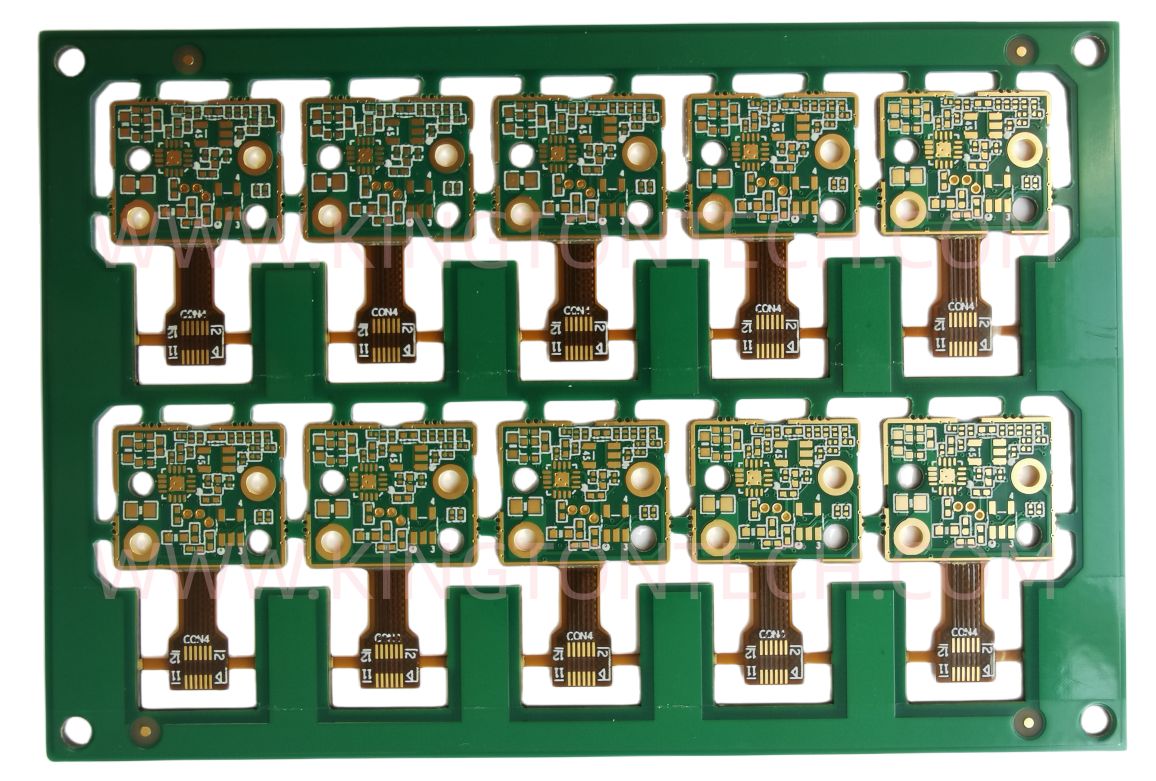

Exploring the Advantages of Flexible-Rigid PCBs in Modern Electronics

In the ever-evolving landscape of electronics manufacturing, flexible-rigid PCBs (Printed Circuit Boards) have emerged as a crucial innovation, enabling the design and production of increasingly compact and versatile electronic devices. These specialized PCBs offer a unique blend of flexibility and rigidity, making them ideal for applications where traditional rigid boards fall short. Let's delve into the world of flexible-rigid PCBs to understand their advantages and diverse applications.

Understanding Flexible-Rigid PCBs

Flexible-rigid PCBs combine the benefits of both flexible and rigid circuit board technologies into a single platform. They consist of multiple layers of

flexible PCB material joined together with layers of rigid PCB material. This hybrid construction allows the PCB to flex and bend in specified areas while maintaining rigidity in others.

The flexible sections are typically made of polyie or polyester film, which can withstand bending and twisting without compromising the integrity of the circuit. Meanwhile, the rigid sections are composed of standard FR4 or other rigid substrates, providing structural support for components that require stability.

Key Advantages

Space Efficiency: One of the primary advantages of flexible-rigid PCBs is their ability to save space in electronic devices. By incorporating flexible sections, these PCBs can conform to the shape of the device, utilizing otherwise unused space efficiently. This feature is particularly valuable in compact consumer electronics like smartphones, wearables, and IoT devices.

Reliability: Unlike traditional flexible circuits, which are prone to damage from repeated bending and flexing, flexible-rigid PCBs offer enhanced durability and reliability. The rigid sections provide support and protect vulnerable components, ensuring long-term performance even in demanding environments.

Reduced Assembly Complexity: Flexible-rigid PCBs can simplify assembly processes by reducing the number of interconnects and eliminating the need for additional connectors or cables. This streamlines manufacturing processes, lowers production costs, and reduces the risk of assembly errors.

Design Flexibility: Engineers have greater design flexibility with flexible-rigid PCBs. They can create intricate three-dimensional layouts that optimize performance and functionality. This flexibility opens up new possibilities for innovative product designs across various industries.

Improved Signal Integrity: The controlled impedance acteristics of rigid sections contribute to improved signal integrity, critical for high-speed digital applications. This ensures reliable data transmission and minimizes electromagnetic interference (EMI).

Applications

Flexible-rigid PCBs find applications in a wide range of industries:

Consumer Electronics: Smartphones, tablets, and wearables benefit from the compactness and reliability of flexible-rigid PCBs.

Medical Devices: Medical equipment often requires flexible circuitry to conform to the shape of the human body while maintaining electronic functionality.

Automotive: Flexible-rigid PCBs are used in automotive electronics for their durability and space-saving advantages.

Aerospace and Defense: These PCBs are ideal for aerospace and defense applications where reliability and compactness are paramount.

Conclusion

Flexible-rigid PCB technology represents a significant advancement in electronic design and manufacturing. Its ability to combine flexibility with rigidity opens up new possibilities for creating smaller, more durable, and innovative electronic devices across industries. As technology continues to evolve, flexible-rigid PCBs will undoubtedly play an increasingly crucial role in shaping the future of electronics.

In summary, the advantages of flexible-rigid PCBs—space efficiency, reliability, reduced assembly complexity, design flexibility, and improved signal integrity—make them a compelling choice for engineers and designers seeking to push the boundaries of electronic innovation.

If you need any more details on the flexible-rigid design rule and fabrication tecnology, please contact me at sales02@kingtontech.com

This article title: Flex-rigid PCB technology and application

This article link: https://www.kingtontech.com/news/show/5125